Gloss is one aspect of visual perception. Considering the psychological impact of products on consumers, it is as important as color. It is defined as “surface attribute”, which makes the object approximate to the shiny or shiny metal texture appearance.

Gloss

The glossiness of the object surface will be affected by many factors, such as the smoothness after polishing, the quantity and type of coating used, and the quality of the substrate.

The manufacturer constantly designs glossy products such as highly reflective car panels, glossy magazine covers, satin black fashion furniture, etc. to maximize the attention of consumers.

Gloss is very important for products. Therefore, the gloss value can be obtained by continuous testing of each product or different batches of products.

Gloss can also be used to measure the surface quality. For example, the glossiness of the surface coating is reduced, indicating that the surface may need to be reprocessed; Other factors that lead to the reduction of gloss value include low viscosity of paint or insufficient quantity of surface coating.

It is these factors that many manufacturing industries need to test the gloss of products, such as automobiles, printing, furniture, food, pharmaceuticals and electronic products.

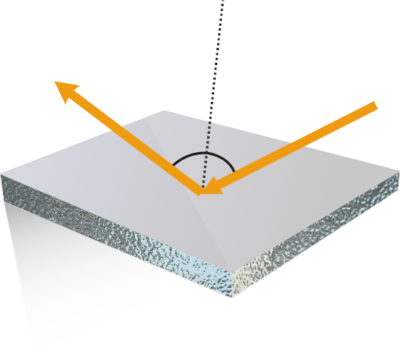

Gloss is measured by shining a certain amount of light on the surface of an object, and then quantifying the amount of reflected light. The test method of light angle and reflection is determined by the object surface and surface appearance.

Therefore, the appropriate angle should be selected to measure the gloss. The NHG268 glossmeter conforms to ISO2813 and GB/T9754 (Chinese national standard). The three angles can fully cover the gloss of all surfaces.

The unit of gloss is (GU), which can be traced to the reference standards of BAM (Germany), NRC (Canada) and NPL (UK).

60 ° is the measurement angle applicable to all surfaces. It is also used as the reference angle when measuring the surface with low gloss 85 ° and high gloss 20 °.

Low gloss: 85 °

To improve the resolution of low-gloss surface. The gloss can be measured at 85 °. When the glossiness value of the object surface measured at 60 ° is lower than 10GU, the 85 ° angle is recommended.

When measuring different gloss texture or slightly uneven surface with 85 °, it is necessary to take the average value of multi-point measurement.

High gloss: 20 °

20 ° measuring angle can improve the resolution of high-gloss surface. When the photometric value of the object surface measured by 60 ° is higher than 70GU, it is recommended to select 20 ° angle for measurement.

The 20 ° angle (light path) is very sensitive to the fog phenomenon on the object surface. Because fog shadow is a unique phenomenon of high-gloss surface.

This instrument is a precision measuring instrument. During the measurement, the drastic changes in the external environment of the instrument should be avoided, such as the flicker of ambient light and the rapid change of temperature.

During the measurement, the instrument shall be kept stable, the measuring mouth shall be close to the object to be measured, and shaking and displacement shall be avoided; This instrument is not waterproof and cannot be used in high humidity environment or water mist.

Keep the instrument clean, avoid water, dust and other liquid, powder or solid foreign matters entering the measuring caliber and inside the instrument, and avoid impact and collision on the instrument.

After the instrument is used, it shall be shut down, and the instrument and standard board shall be put into the instrument chamber for safekeeping.

The instrument shall be stored in a dry and cool environment.

Users are not allowed to make any unauthorized changes to this instrument. Any unauthorized change may affect the accuracy of the instrument and even irreversibly damage the instrument.

Gloss meters AGM-580 are mainly used in the surface gloss measurement for paint, plastic, metal, ceramics, building materials. It conforms to the DIN67530, ISO2813, ASTM D523, JIS Z8741, BS 3900 Part D5, JJG696 standards and so on.

AGM-500PRO Gloss Meter with Single Angle:

Tags:AGM-500PRO , AGM-580Your email address will not be published. Required fields are marked *