LED heat dissipation has become more and more attention by people, this because its Lumen decay or its life is directly related to its junction temperature, bad heat dissipation, junction temperature is high, life is short, according to the Arrhenius method, each drop 10 ℃ temperature, life will extend 2 times. From fig 1 we know, if the Junction Temperature can be controlled on 65℃, then the life can be up to ten hundred thousand hours if the Lumen decay to 70%, but the actual LED heat dissipation is far away from this requests, so that the service life of LED lamps becomes one of the major problems to affecting its performance.

The Relationship between LED Heat Dissipation and Junction Temperature

Fig 1 The relationship between Lumen Maintenance and Heat Dissipation

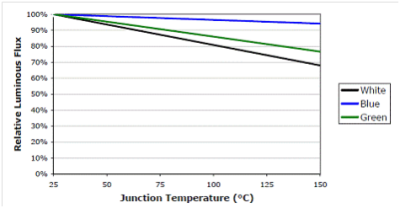

The factor of LED heating is that unsuccessful converting all electric energy directly into luminous energy, but part of converted to heat energy. Currently LED luminous efficacy only 100 lm/W, the electro-optic conversion efficiency is only about 20 ~ 30%. That is to say, about 70% electrical energy into heat energy, resulting in a junction temperature. Junction temperature not only influence life, also directly affect the luminous efficiency, see fig 2:

Junction Temperature

Fig 2 The relationship between Luminous Flux and Junction Temperature

Suppose the flux is 100% when the Junction Temperature is at 25℃, then the Junction Temperature up to 60℃, it’s flux is 90%; Junction Temperature up to 100℃, the flux drop to 80% etc, visible to improve heat dissipation, junction temperature control is very important thing. In addition, LED heating also makes the spectrum moving: color temperature rise, forward current increases(constant voltage power supply), reverse current also increases, the thermal stress increases and will accelerated aging of phosphor proxy resin and so on.

Therefore, Lisun launched a LED junction temperature resistance performance tester, it can test the LED junction temperature, K coefficient, forward voltage, forward current curve along with the changes of time, it is for the LED manufacturer provides better heat dissipation solutions.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Surge Generator, EMC Test Systems, ESD Simulator, EMI Test Receiver, Electrical Safety Tester, Integrating Sphere, Temperature Chamber, Salt Spray Test, Environmental Test Chamber, LED Test Instruments, CFL Test Instruments, Spectroradiometer, Waterproof Test Equipment, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp: +8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp: +8618917996096

Your email address will not be published. Required fields are marked *