Introduction

The EU RoHS 2.0 directive, issued in 2011, is a critical regulation aimed at limiting the use of hazardous substances in electronic and electrical products to protect human health and the environment. To comply with this directive, electronic and electrical products must undergo RoHS 2.0 testing to prove they do not contain six harmful substances: lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr6+), polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE). This article provides a detailed overview of the RoHS 2.0 directive and the technical details and operational standards of its testing equipment.

Scope and Impact of the RoHS 2.0 Directive

The RoHS 2.0 directive applies to a wide range of products, including electronic, electrical, communication devices, toys, and security information products. It covers not only complete products but also the components, raw materials, and packaging used in their production, impacting the entire supply chain. In the long run, the implementation of the RoHS 2.0 directive has positive implications for humanity by reducing the harmful effects of these substances on the environment and human health.

Overview of RoHS 2.0 Testing Equipment

RoHS 2.0 testing equipment is specifically designed to optimize product performance and enhance safety levels. The equipment incorporates the latest generation of high-voltage power supplies and X-ray tubes, improving reliability and testing efficiency. Typically, RoHS 2.0 testing equipment is divided into two main categories: Wavelength Dispersive X-ray Fluorescence Spectrometers (WDXRF) and Energy Dispersive X-ray Fluorescence Spectrometers (EDXRF).

LISUN EDX-2 series energy scattered X-ray fluorescent spectrometer is realized by analyzing the element characteristic X-ray wavelength and strength of the element emitted by the sample. The elements contained in the sample are determined according to the different elements characteristics of the X -ray wavelength, and the content of the element in the sample can be determined by comparing the strength of the different elemental spectrum.

By cooperating with the software developed by LISUN, it has the following three typical applications:

Typic Application 1(LISUN Model:EDX-2A、EDX-2AB、EDX-2AC、EDX-2ABC、EDX-2T): RoHS 1.0 Directive Testing for electronic and electrical products, components, plastics and plastic parts. Click here to download the ROHS 1.0 test report sample.

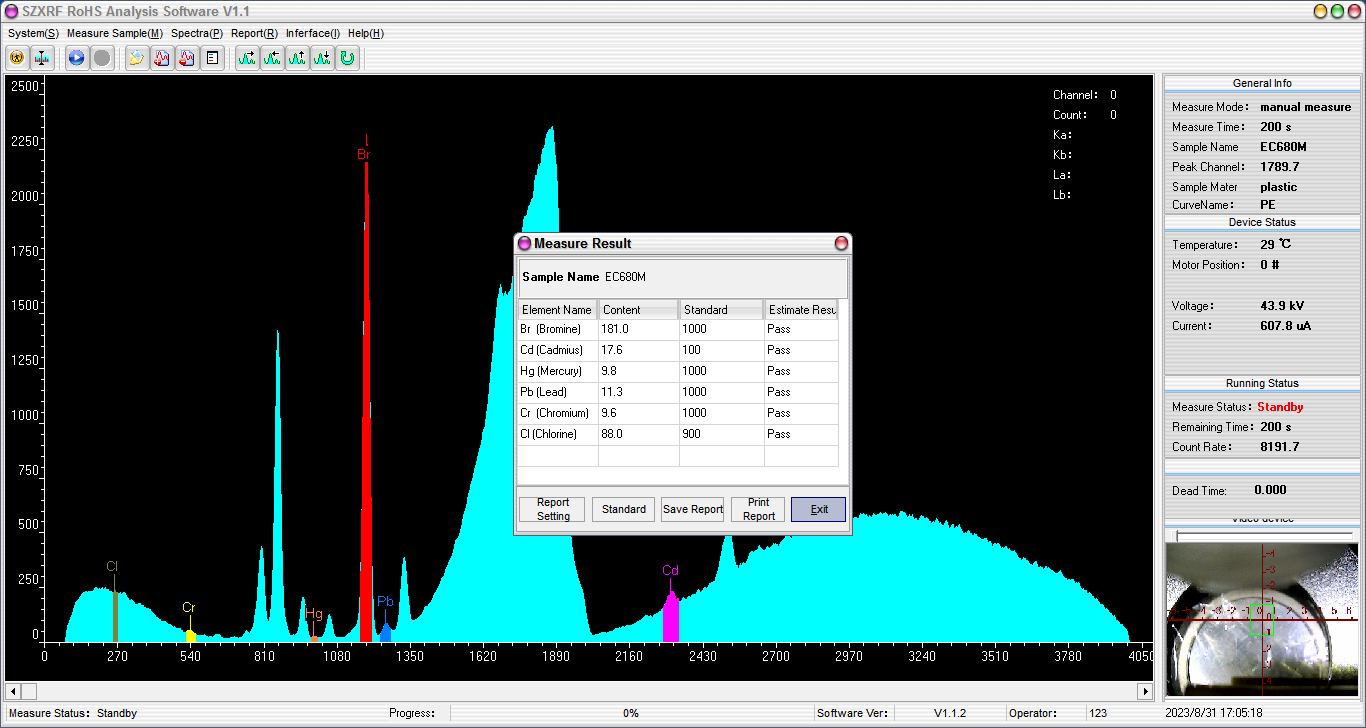

EDX-2A Software RoHS Testing

Typic Application 2(LISUN Model:EDX-2AB、EDX-2ABC、EDX-2T): Elements Analysis for precious metals, alloys, metals, coatings and other elements with absolute content value testing. The Periodic Table of Elements from 16-S to 92-U. (Note: EDX-2T can test all elements from 11-Na to 92-U). Click here to download the alloy analysis test report sample.

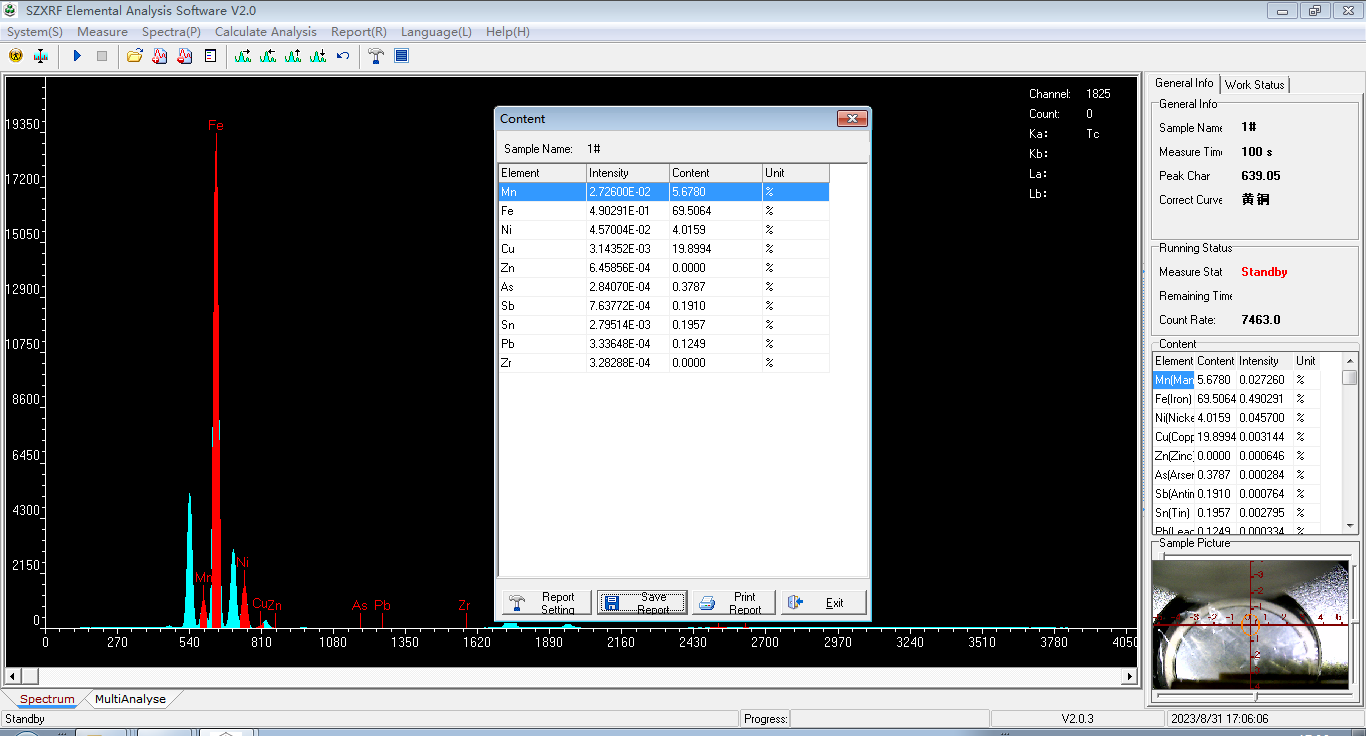

EDX-2A Software Element Analysis

Typic Application 3(LISUN Model:EDX-2AC、EDX-2ABC、EDX-2T): Coating and Plating Thickness Measurement Function with absolute thickness value testing. Click here to download the coating and plating thickness test report sample.

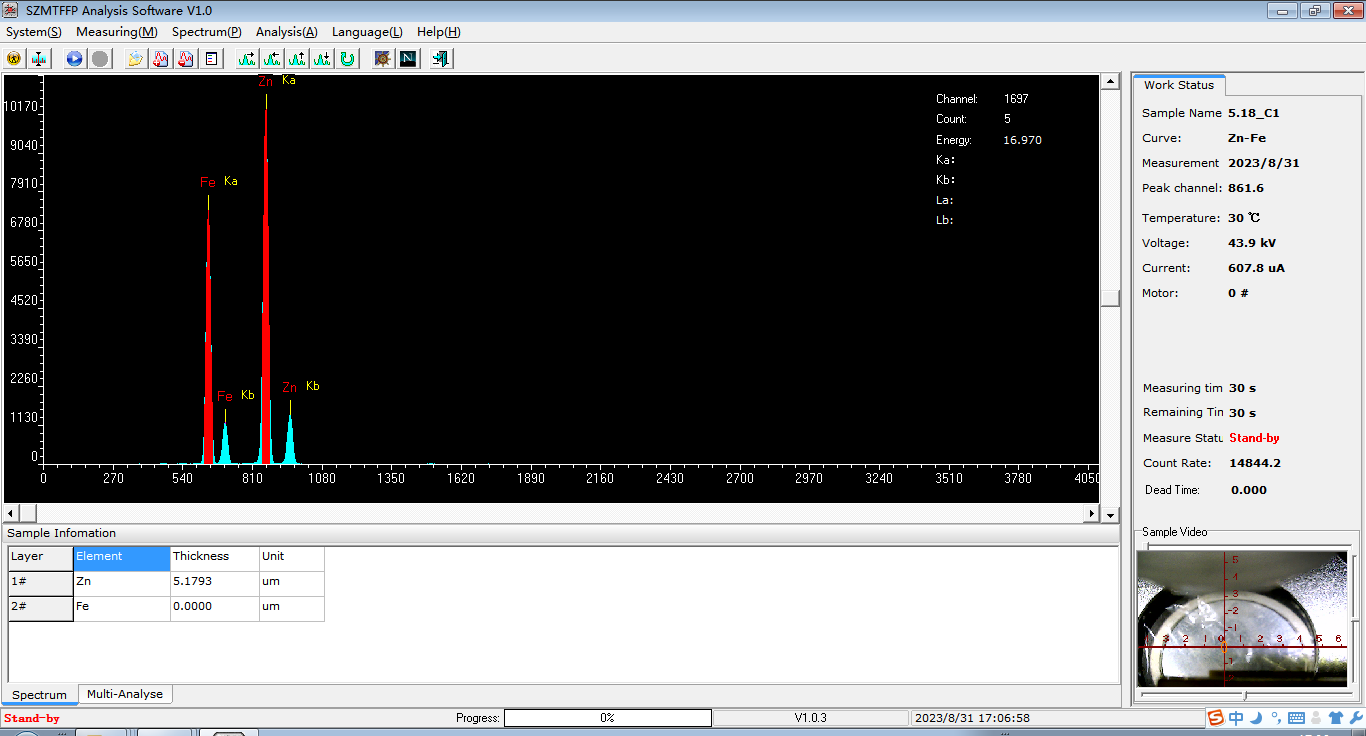

EDX-2A Thickness Gauge

Operational Standards for RoHS 2.0 Testing Equipment

Strict adherence to operational standards is crucial when using RoHS 2.0 testing equipment to ensure the accuracy of tests and the longevity of the equipment.

Safety Operation Points

• Avoid Ionizing Radiation Hazards: The equipment generates ionizing radiation during testing. Ensure the device is not directed at people or open air and avoid holding samples by hand during testing.

• Protection Measures: Do not open the protective cover of the equipment or direct the testing instrument at the human body while the device is operational.

• Regular Calibration: Calibrate the equipment each time it is turned on and after every four hours of continuous operation to ensure accurate test results.

• Professional Operation: Only trained personnel should operate the equipment. Strictly follow operational procedures to prevent inaccurate test results and equipment damage due to improper handling.

• Shutdown Procedures: After testing, click the “Settings” interface’s X-ray tube button. In the dialog box that appears, click the “Turn off high voltage power” button, then click “OK.” Wait until the tube voltage and current drop to safe levels before proceeding. Finally, click the “Close” button in the upper right corner of the interface and wait for the software to close before shutting down the hardware.

Calibration Steps

Calibration is crucial to ensure the equipment’s accuracy and reliability. Perform calibration each time the equipment is turned on and after every four hours of continuous operation. The steps include:

• Start Calibration Program: Follow the instrument manual to initiate the calibration program.

• Use Standard Samples: Use standard samples with known compositions for calibration to ensure accurate readings.

• Adjust Parameters: Based on the calibration results, adjust the equipment parameters to ensure the accuracy of subsequent tests.

The RoHS 2.0 directive and its testing equipment play a vital role in protecting the environment and human health. Proper use and maintenance of the testing equipment ensure that electronic and electrical products comply with the RoHS 2.0 directive, thereby reducing the impact of harmful substances on the environment and human health. As a key factor in measuring the quality of electronic and electrical products, RoHS 2.0 testing equipment will continue to play an important role in future developments.

Tags:EDX-2AYour email address will not be published. Required fields are marked *