I. Dimensions

Plugs shall comply with Standard Sheet

1. Compliance is checked by measurement and byneans of the gauges shown in figures 1 and

2. The use of the gauges shown in figure 1 for checking the diameter of the pins, is optional.

II. Protection against electric shock

1. Live parts of plugs, with the exception of the bare metal parts of the pins, shall not be accessible.

Compliance is checked by the following test.

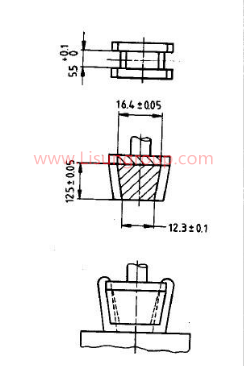

Gauge for Checking Impossibility of Single-pole Insertion of Plugs Into Socket-outlets without Position Rack

The standard test finger shown in figure 3 is applied in every possible position, except on the bare metal parts of the pins. An electrical indicator with a voltage between 40V and 50V is used to show contact with the relevant part.

For plugs made of material that is likely to influence the requirement, the test is repeated at an ambient temperature of (35±2)℃, the plugs being also at this temperature. During this additional test, the plugs are subjected for (60+5)s to a force of (75+3)N, applied through the tip of a straight unjointed test finger of the same dimensions as the standard test finger shown in figure 3. The straight unjointed test finger is applied to all plapes where yielding of the insulating materlal could impair the safety of the plug.

Gauge for Checking Impossibility of Single-pole Insertion of Plugs Into Socket-outlets without Position Rack

During this test,the plug shall not deform to such an extent that thpse dimensions shown in the standard sheet which ensure safety are unduly altered and no live part shall be accessible.

2. It shall not be|possible to make connection between a pin of aplug and a live socket contact of a socket-outlet while the other pin is accessible.Compliance is checked by means of the gauge

shown in figure 4. For plugs with enclosures or bodies of thermoplastic material, the test is made at an ambient temperature of (35±2)℃, the plug and the gauge both being at this temperature.

3. External parts of plugs, with the exception of the pins, shall be of insulating material. Compliance is checked by inspection. Lacquer or enamel is not deemed to be an insulating material for the purpose of this sub-clause.

III. Construction

1. Plugs according to this standard shall be non-rewirable,i.e. they shall be such that:

– the cord can not be separated from the plug without making this permanently useless, and

– the plug cannot be opened by hand or by using a general purpose tool,e.g.a screwdriver.

A plug is considered to be permanently useless when, for re-assembling the plug, parts or materials other than the original are to be used. Compliance is checked by inspection.

2. Switches, fuses or lampholders shall not be incorporated in plugs.

Compliance is checked by inspection.

3. Pins of plugs shall be solid and shall have adequate mechanical strength. Compliance is checked by inspection and by the tests of clause 13.

4. Pins of plugs shall be locked against rotation and adequately fixed into the body of the plug. Compliance is checked by inspection, by manual test and by the tests of 13.1 and 13.4.

5. Plugs shall be provided with soldered,welded, crimped or equally effective permanent connections; screwed or snap-on connections shall not be used.

Connections made by crimping a presoldered flexible conductor are not permitted, unless the soldered area is outside the crimping area. Compliance is checked by inspection.

6. Plugs shall be shaped in such a way and made of such a material that they can easily be withdrawn by hand from a socket-outlet.

In addition, the gripping surfaces shall be so designed that the plug can be withdrawn without having to pull the cord. Compliance is checked by inspecting whether the plug has either:

– a usable length for gripping of at least 55 mm in axial direction, or

– such indent(s) that a ball with a diameter of (12±0,1)mm can penetrate radially into the body at least 2 mm from two opposite directions or at least 4 mm from one direction.

In case of non-compliance with the above requirements, a gripping test shall be performed. The gripping test is under consideration.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *