Product No: GDWJS-0100D

It is applied to heat resistance, humidity resistance, dry resistance, high and low temperature adaptability test, low temperature constant temperature and storage of electronic and electrical products, electrical appliances, instruments, plastics, PVC and other raw materials, electronic components and devices. And also suit for optical fibers, crystals, High and low temperature adaptability test of precision inductor, PCB, LCD and other products. It is a reliability test equipment for quality control engineering. It is also suitable for quality supervision bureaus, scientific research units, colleges and universities to test product performance and quality.

Standard:

• GB/T2423 “high and low temperature damp heat alternating test standards”

• GB/T 2423.1-2008 “Environmental test of electrical and electronic products – Part 2: Test method Test A: Low temperature”

• GB/T 2423.2-2008 “Environmental test of electrical and electronic products – Part 2: Test method Test B: High temperature”

• GB/T 2423.3-2006 “Environmental test of electrical and electronic products – Part 2: Test method Test Cab: Constant damp heat test”

• GB/T 2423.4-2008 “Environmental test of electrical and electronic products – Part 2: Test method Test Db: Alternating damp heat (12h + 12h cycle)”

• GJB150.4A-2009 “Low temperature test”

• GJB150.3A-2009″ High temperature test”

Technical Specifications:

| Working size: | D 4000×W 3000×H2200mm |

| External Dimensions | D 4600×W 4200×H2580mm (No motor size: for reference only) |

| Note: The height of the container is 2600mm | |

| Temperature Range: | -30℃~+120℃(no load) |

| Temperature Resolution: | 0.01℃ |

| Humidity resolution: | 0.1%RH |

| Temperature fluctuation: | ±0.5℃ |

| Temperature deviation: | ≤±2℃ |

| Temperature uniformity: | ≤2℃ |

| Heating rate: | 0.5 ℃/min (average over the whole process, no load) |

| Cooling rate: | About 0.5 ℃/min (average over the whole process, no load) |

| Humidity range | 20~95%RH |

| Relative humidity deviation | ≤-3%~+2%RH (when humidity is >75%RH) (with load); |

| ≤±5%RH (when the humidity is ≤75%RH) (with load). | |

| Humidity fluctuation | ≤±3 %RH(with load) |

| Time setting range: | 0~9999 hours |

| Air speed | 0.3 m/s |

| noise:: | One meter directly in front of the center of the gate, measured at a height of 1.5 meters, the noise is ≤75dB |

| Equipment load-bearing: | ≥600kg |

| Power supply: | 380V/50HZ |

| Equipment structure characteristics: | |

| This equipment is assembled by whole chamber before delivery. | |

| Surface material: plastic-coated cold-rolled steel plate T/1.0mm (standard color) | |

| Inner surface material: wall plate, roof plate: stainless steel plate (SUS304) T/1.0mm | |

| Bottom plate: stainless steel plate (SUS304) T/1.0mm | |

| Warehouse board thickness: T/100mm (insulation material is rigid foamed urethane) | |

| Base plate load-bearing pressure: uniform load ≥ 600kg/m2, total base plate load-bearing ≥ 1000kg | |

| Material: Same as warehouse board (standard color) | |

| Thickness: T/100mm | |

| Double door width 2000 × height 2000mm (2 door size) | |

| The door handle can be opened both inside and outside so that testers can open it freely from a closed room. | |

| The door has an anti-lock safety device to prevent accidents. | |

| Silicone rubber sealing strips and anti-frost electric heating devices are used, and a multi-layer vacuum electric heating glass observation window is installed on the door. | |

| There are 2 observation windows (one small observation window is installed on each door) , made of tempered 250°C annealed glass, which complies with CCC international safety standards and is explosion-proof and shatter-proof; aluminum alloy hollow insulation is used between the laminated glasses, and the glass surface has Thermal conduction function, when the glass generates condensation water, it will heat and defrost automatically; visible size, small observation window size W400mm×H600mm | |

| 1 test hole, with a φ100mm lead hole on the left or right side of the chamber, equipped with a high and low temperature resistant silicone rubber plug (the opening position shall be confirmed on site) | |

| • The lighting casing is made of tempered glass with a thickness of 3mm; there is a mesh cover on the outside, in accordance with the international standards for chemical industry and petroleum; | |

| • it is explosion-proof, waterproof and dustproof IPX6 IPX8; | |

| • there are 2 explosion-proof lights on the top, one each side by side; the control switch is outside the chamber on the control panel or in the touch screen control instrument | |

| Air supply circulation system: | |

| Motor | Using imported fan motor and high temperature resistant aluminum alloy circulation fan to achieve forced convection vertical diffusion circulation |

| Air circulation | The air circulation adopts an upper air outlet and lower return air design. The wind pressure and wind speed meet the test standards, and the temperature stabilizes quickly when the door is opened and closed. |

| Centrifugal fan | The use of high-quality centrifugal fans for strong air circulation avoids any dead spots and can evenly distribute the temperature in the test area; energy saving and quietness better ensure a good office environment and working environment for operators, and comply with current international and domestic environmental protection requirements. |

| Heating system: | |

| The heating system adopts hot air circulation heating method, with uniform temperature distribution and a completely independent system. | |

| The temperature control output power is calculated by a microcomputer, and the heating power is automatically controlled according to the internal load to achieve high-precision and high-efficiency power consumption, which is more environmentally friendly and energy-saving. | |

| Main components of the system: heating tube, solid state relay, etc. | |

| Humidification system | |

| Using an all-stainless steel shallow surface evaporative humidifier, the humidification and humidification dehumidification systems are completely independent through the humidification boiler; | |

| Water level control: adopt mechanical float water valve to avoid electronic malfunction | |

| Water supply system: automatic replenishment with tap water | |

| Humidification system consists of: humidifier, water level controller, connecting water pipe, hose | |

| Humidity Sensor Finland Vaisala digital Humidity Sensor | |

| Refrigeration system: imported German “Bitzer” semi-hermetic refrigeration compressor | |

| The German Bitzer semi-hermetic refrigeration compressor mainly consists of a cylinder block, a piston, a connecting rod, a crankshaft, a cylinder head, and a crankshaft oil pan. It uses compressed air to discharge and return the refrigerant in a cycle, and circulates the air within a certain period of time. The cold energy evaporates to the evaporator, and then the air duct system takes the cold energy out; | |

| In the refrigeration process, we have many successful technical engineers with many years of experience, reasonable configuration, and perfect industrial production. The main core of refrigeration lies in the configuration and process manufacturing process. We also firmly believe that China’s technology will continue to improve and become the value of German mid-range products, bringing great convenience to the domestic market; | |

Refrigeration unit system

Refrigeration structure system

Refrigeration principle and structure:

• Refrigeration system and compressor. In order to ensure the cooling rate and minimum temperature requirements of the test chamber, the refrigeration system of this test chamber adopts a cascade refrigeration system composed of imported compressors. This refrigeration system has the characteristics of reasonable matching, high reliability and ease of use. Advantages such as easy maintenance;

• Working principle of refrigeration: The refrigeration cycle all adopts the reverse Karo cycle, which consists of two isothermal processes and two adiabatic processes. The process is as follows: the refrigerant is adiabatically compressed to a higher pressure by the compressor, consuming work to exhaust the gas. The temperature rises, and then the refrigerant conducts heat exchange with the surrounding medium isothermally through the condenser and transfers heat to the surrounding medium. After the refrigerant passes through the shut-off valve, the adiabatic expansion does work, and the temperature of the refrigerant decreases. Finally, the refrigerant absorbs heat isothermally from the higher temperature object through the evaporator, causing the temperature of the object to be cooled to decrease. This cycle repeats itself to achieve the purpose of cooling;

• The design of the refrigeration system applies energy adjustment technology, an effective processing method that can not only ensure the normal operation of the refrigeration unit, but also effectively adjust the energy consumption and cooling capacity of the refrigeration system, reducing the operating costs of the refrigeration system. Descending to a more economical state;

• High-quality oxygen-free copper pipe, nitrogen-filled welding;

• Cooling method: water cooling

| Introduction to refrigeration components: | |

| Oil and gas separator | The oil-vapor separator has the ability to separate oil from the refrigerant mixture, thereby promoting the efficient operation of the refrigeration and air-conditioning system and saving energy. Its function is to pass the mixture of refrigerant and oil returned to the compressor through the filter and baffle device of the separator, so that the fine particles of oil in the mixed gas are separated and collected at the bottom of the oil separator. The bottom of the oil separator has a The float-operated needle valve opens; |

| Danbus thermal expansion valve: | It is specially designed for refrigeration applications and is suitable for various refrigeration equipment such as cold storage, freezers, ice cream machines, ice machines and transportation cooling devices. Mainly divided into three series: TI (replaceable spool type), TER (integral type), and TC (split type). |

| Imported Castito solenoid valve | Imported Castot solenoid valves are mainly used for deformed regulation and medium flow control of the refrigeration system. |

| Dangus filter drier | Features: 80% 3A molecular sieve and 20% activated aluminum. The maximum working pressure can reach 42Bar. |

| Auxiliary refrigeration: | Steam hair Device: fin type |

| Cold Media: Imported R404 and 243 | |

| Cold Condense Device: water-cooled coil | |

Cooling system: water cooler (auxiliary compressor cooling)

1. Used to cool down the compressor

2. Installed indoors or inside or outside

3. Good cooling effect and easy maintenance

4. Energy consumption: 30P

5. Overall dimensions: L2200*W1100 (limited)*H1810

Note: The installation site width is limited to 1100mm

Water chiller

Temperature and humidity controller: Taiwan Weilun ” 7-inch” LCD touch screen temperature and humidity control instrument (with USB interface, data can be copied out and saved):

• 7-inch true color touch screen

• Temperature controller specifications: Accuracy: 0.1℃ Resolution: 0.1℃

• Interface language type: Chinese and English menu operations are used;

• Two control methods: program/fixed value, worry-free switching between fixed value control and program control

• Sensor type: Two PT100 inputs (electronic sensor input optional)

• Control method: thermal balance temperature and humidity regulation method

• Equipped with RS232 or RS485 computer interface for human-computer dialogue, online data transmission and remote control functions, and can be equipped with a printer (USB function is optional)

• Distribution intelligent computer control support software system

• The instrument can display setting parameters, current running program number, current running step and step remaining time, heater working status, program running trend, and remaining number of cycles

• The program runs automatically and automatically cuts off the power after shutdown.

• Can realize manual PID control and PID self-tuning function

• The instrument can display the eight-day program operation curve

• Able to implement scheduled automatic operation and timely operation

• Automatically perform fault display and alarm

• Password protected

• Program editing: 120 groups of programs can be programmed, each group of programs can have a maximum of 100 segments, all groups can be cycled, and some segments can be cycled;

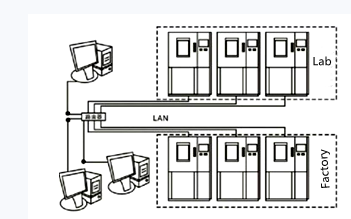

Remote monitoring diagram

Remote monitoring diagram

| Introduction to some electrical components | |

| small relay | Use imported Omron small relays |

| AC contactor | Using Schneider AC contactor imported from France |

| solid state relay | Using Good solid state relay imported from the United States |

| delay relay | After the power is cut off, the relay starts to delay. After the delay reaches the set time, the relay starts to act on a set of delay contacts. |

| breaker | Using French Schneider circuit breakers |

| Temperature Sensor | Using Taiwan Yifan PI100 sensor |

| Humidity Sensor | Vaisala Electronic Humidity Sensor |

| Temperature range: -70~200℃ | |

| Humidity range: 0~100%RH | |

| Accuracy: ±1.5%RH, ±0.3℃ | |

| Phase sequence protector | French Schneider |

| Temperature Sensor | PT100, accuracy 0.1℃, grade A, deviation ±0.5℃. |

Security protection system:

• Studio over-temperature protection;

• Safe and reliable grounding protection device;

• Heater short circuit and overload protection;

• Water shortage protection;

• Compressor overpressure protection;

• Compressor motor overheats;

• Overcurrent protection;

• Fan motor overheating protection;

• Overall power supply phase sequence and phase loss protection;

• Leakage Protection;

• The test chamber shell has protective functions such as grounding protection and adopts multi-color light and sound and light alarms.