Electrostatic Discharge (ESD) Immunity Testing

Electrostatic discharge (ESD) immunity testing is a crucial aspect of electromagnetic compatibility testing. The national standard for ESD immunity testing is GB/T 17626.2, which is equivalent to the international standard IEC 61000-4-2. ESD is a common natural phenomenon, especially prominent in dry environments. For example, when a person walks on a synthetic fiber carpet, the friction between the shoes and the carpet can cause the body to accumulate a charge exceeding 10^-6 coulombs (depending on the resistance between the shoes and the carpet). In this human/carpet/ground system, the average capacitance is approximately tens to hundreds of picofarads (pF), potentially generating voltages up to 15 kilovolts (kV).

Studies have shown that different individuals generate varying ESD current pulses, with rise times ranging from 100 picoseconds (ps) to 30 nanoseconds (ns). Electronic engineers have observed that ESD frequently occurs when a person contacts semiconductor devices, which may lead to the breakdown of multiple layers of semiconductor materials, causing irreversible damage. Additionally, ESD and the resulting electromagnetic field variations can disrupt and damage the normal operation of electronic equipment.

LISUN designed and manufactured Electrostatic discharge simulator is highest electrostatic voltage can be up to 30 kv, which is enough to cover the most severe standard grade of electrostatic voltage requirement (the voltage requirements of the grade 4 air discharge electrostatic is 15 KV). The ESD test gun can be used for the most of electrical and electronic equipment for electrostatic discharge test, and also can ensure comparability and reproducibility of test.

Purpose of ESD Immunity Testing

The GB/T 17626.2 standard describes scenarios where the human body can become charged through friction in low humidity environments. When a charged person contacts a device, they may discharge and affect the device’s functionality. ESD immunity testing primarily simulates the following two scenarios:

• Direct Discharge: Discharge occurs when an operator directly touches the equipment, and the impact of this discharge on the equipment’s operation.

• Indirect Discharge: Discharge occurs when an operator touches an object near the equipment, affecting the test equipment indirectly.

Potential Consequences of ESD

• Permanent Damage: Direct energy exchange through discharge may damage semiconductor devices within the equipment, leading to permanent failure.

• Malfunctions: Discharge, whether direct or indirect, can induce near-field electromagnetic field changes, causing the equipment to malfunction.

Discharge Methods

Direct Discharge

Contact discharge is the preferred method. Only when contact discharge is not feasible (e.g., surfaces with insulating layers or gaps between computer keys) is air discharge used as an alternative.

Indirect Discharge

Indirect discharge includes horizontal coupling plane (HCP) and vertical coupling plane (VCP) methods to simulate ESD scenarios in the actual usage environment.

Choice Between Contact Discharge and Air Discharge

Contact discharge is preferred due to the limitations observed with air discharge in the predecessor of IEC 61000-4-2, IEC 801-2, which exclusively used air discharge. The repeatability and comparability of test results using air discharge were found to be inadequate due to the following factors:

• Proximity Speed: The speed at which the discharge electrode approaches the Device Under Test (DUT) affects the discharge current waveform.

• Surface Shape: The shape of the DUT’s surface influences the electric field distribution of the electrode.

• Environmental Conditions: Temperature, humidity, and air pressure impact the discharge process.

• Discharge Voltage: The discharge voltage affects the spectral characteristics of the discharge current waveform. For example, the rise time of an 8 kV discharge current typically ranges from 1 ns to 5 ns, while higher voltages may have rise times of 5 ns to 30 ns.

Conclusion

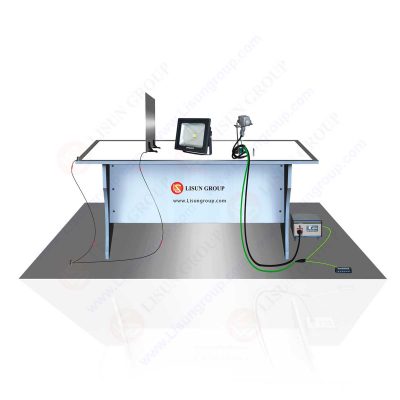

One of LISUN successful case for customer who installed whole set of ESD immunity test instrument also include ESD Desk as below picture for reference:

ESD Standard DESK

ESD immunity testing is an essential method to ensure that electronic devices can operate normally in actual usage conditions. By adhering to the GB/T 17626.2 (IEC 61000-4-2) standards, manufacturers can identify and improve the ESD immunity of their devices, enhancing product reliability and safety. Proper ESD protection measures and standardized testing procedures are vital to ensuring the performance and lifespan of electronic equipment.

Tags:ESD61000-2Your email address will not be published. Required fields are marked *