What is the Electric Discharge?

This should be the main culprit that causes all electronic components or integrated circuit systems to cause excessive electrical stability damage. Because the electrostatic voltage is usually very high (more than thousands of volts), this damage is devastating and permanent, which will cause the circuit to burn directly. So preventing static damage is the number one problem for all IC design and manufacturing.

Electric Discharge is usually produced by artificially, such as production, assembly, testing, storage, transportation, etc., may make Electric Discharge accumulate in the human body, instruments or equipment, and even the components itself will accumulate static electricity. In the case, the contact of these power -based objects will form a discharge path, which instantly causes the electronic component or system to be damaged by Electric Discharge (this is why the computer had to wear a static loop at the work table to prevent the human body from being used to prevent the body from the human body. Electrostatic damage chip), like the charge stored in the clouds, instantly penetrates the clouds and produces severe lightning, which will split the ground, and it is usually when the air humidity is likely to form conductive passing.

Static electricity in life

So, how to prevent static discharge damage? First of all, of course, change the static electricity from the source (such as reducing friction, wearing less wool sweaters, controlling air temperature and humidity, etc.). Of course, this is not the focus of our discussion today.

When we are going to discuss today, how to involve the protection circuit in the circuit. When there is static electrical electronic components or systems when there is static electricity, we can self -protect and avoid being damaged by electrostatic (actually install a lightning needle). This is also the number one problem for many IC design and manufacturers. Many companies have a team that specializes in design ESD. Today, I will gradually explain the principles and attention of ESD protection from the most basic theory. You will find the PN mentioned earlier. Kid/diode, triode, MOS tube, Snap-back all use it.

When the previous topic explains the theory of the PN knot diode, I have mentioned that the diode has a characteristic: positive direction and reverse cut off, and the anti -bias voltage continues to increase it. . This is exactly the theoretical basis we need to design static electricity protection. We use this reverse cut -off characteristic to make this bypass at a disconnected state when working normally. The bypass pathway protects the internal circuit or gate (is it similar to a spill in the sink in the home, preventing the faucet from forgetting to close the entire bathroom flood).

So the question comes, is this protection circuit that breaks completely? Is it a one -time? The answer is of course not. There are two types of PN knots, which are electricity breakdown and thermal breakdown. Electric penetration refers to the avalanche breakdown (low concentration) and Zina breakdown (high concentration). The flow of the flowing power from the Electron-Hole, so it can be restored. But thermal breakdown is irreversible because the heat agglomeration causes silicon (Si) to be burned by melting. Therefore, we need to control the current control current, and generally connect a high resistance in the protective diode.

In addition, can everyone understand why the ESD area cannot be used to use? There is also a theory for everyone. ESD is usually next to the PAD of the chip input terminal. We cannot be in the chip, because we always want the outside electrical electricity to be leaked as soon as possible, and there will be delay in it (There are diodes next to the chip of the previous anatomy. There are even two -level ESD to achieve the purpose of dual protection.

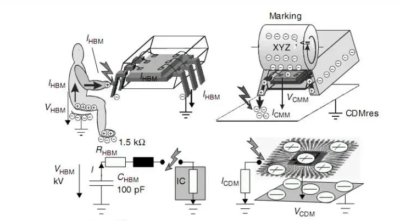

Before talking about the principle of ESD and Process, let’s talk about the standards and test methods of ESD. According to the method of static electricity and the damage mode of the circuit, it is usually divided into four test methods: the human discharge mode (HBM: Human-Body Model ), Machine Model (Machine Model), component charging mode (CDM: Charge-Device Model), and electric field sensor mode (FIM: Field-Induced Model), but the industry usually uses the first two modes to test (HBM, MM).

1. Human discharge mode (HBM):

Of course, the human body friction produced the charge and the charged charge released by the chip caused the chip to burn and break through. This is the reason for touching with others in autumn. The industry also has the ESD standard of HBM (MIL-STD-883C Method 3015.7, the equivalent human capacitor is 100pf, the equivalent human resistance is 1.5kohm), or the international electronics industry standard (EIA/JESD22-A114-A). It is specified, depending on which one you want to follow.

If it is MIL-SD-883C METHOD 3015.7, it stipulates that those smaller than <2KV are class-1, and on 2kV ~ 4KV for Class-2, 4KV ~ 16KV as Class-3.

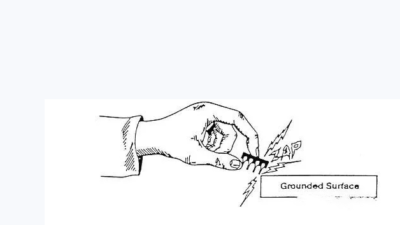

Grounded surface

2. Machine discharge mode (MM):

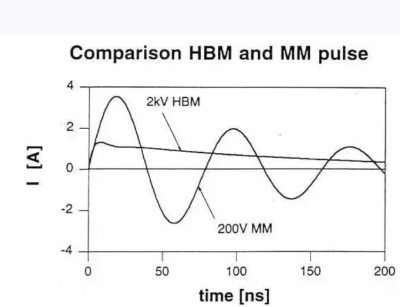

Of course, when the electrostatic touch chip generated by the machine (such as ROBOT) is released by the PIN foot when the electrostatic touch chip generated by the machine, the secondary standard is the EIAJ-IC-121 Method 20 (or the standard EIA/JESD22-A115-A).), the capacitor is still 100pf. Because the machine is metal and the resistance is 0, the discharge time is very short, which is almost between MS or US.

However, the more important problem is that because the equivalent resistance is 0, the current is very large, so even the 200V MM discharge is more harmful than the 2kV HBM discharge. And the machine itself has a coupling effect because there are many wires, so the current changes with time changes.

Comparisom HBM and MM pulse

The ESD test method is similar to the GOI test in FAB. After specifying PIN, give him an ESD voltage. After a period of time, then return to test the electrical to see if it is damaged. Then measure electrical, so repeatedly until the breakdown, the breakdown voltage at this time is ESD Failure Threshold Voltage. Usually we all give the circuit three voltage (3 ZAPS). In order to reduce the test cycle, the 70% ESD threshold of the standard voltage is usually used for starting voltage. Each STEP can adjust 50V or 100V as needed.

LISUN Solution:

LISUN ESD simulator guns (Electrostatic Discharge Generator/Electrostatic Gun/ESD Guns) is in full compliance with IEC 61000-4-2, EN61000-4-2, ISO10605, GB/T17626.2, GB/T17215.301 and GB/T17215.322.

The static electricity generated by the human body to the object or between two objects may cause the electrical and electronic equipment circuits to malfunction or even be damaged. The ESD generator is designed for the withstanding ESD performance measurement for the assessment of electrical and electronic equipment. ESD61000-2/ESD61000-2A has a LCD touch screen in both English and Chinese.

Electrostatic discharge simulator is highest electrostatic voltage can be up to 30 kv, which is enough to cover the most severe standard grade of electrostatic voltage requirement (the voltage requirements of the grade 4 air discharge electrostatic is 15 KV). The ESD test gun can be used for the most of electrical and electronic equipment for electrostatic discharge test, and also can ensure comparability and reproducibility of test.

LISUN ESD-883D HBM/MM ESD Simulators is specially designed for the antistatic test of semiconductor devices and IC refers to the standard GJB548A-96 method 3015, GJB128A-97 method 1020, MIL-STD-883D, EIAJED-4701, ANSI/ESD STM5.1, ANSI/ESD STM5.2, EIA/JESD22-A114- B, EIA/JESD22-A115-A.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *